Standard pump maintenance shouldn’t mean compromising your formation’s productivity. Traditional well-killing methods often lead to skin damage, costly fluid management, and extended recovery times.

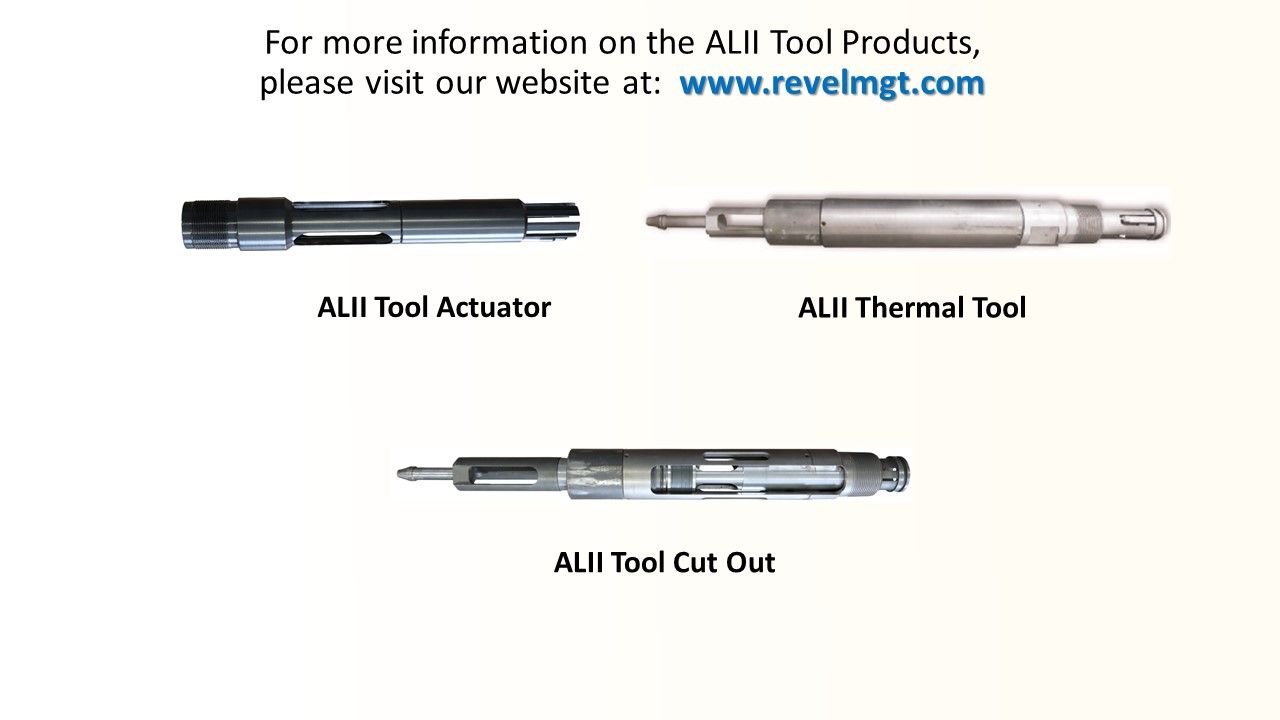

The ALII (Artificial Lift Intake Isolation) tool provides a reliable downhole barrier that streamlines operations and protects the asset.

Operational Benefits of ALII:

✅ Pressure Isolation & Zero-Kill Operations: Acting as a high-integrity isolation valve at the end of the tubing, ALII allows for pump changes without killing the well. You maintain wellbore integrity and avoid the risks associated with kill fluids. ✅ Formation Protection: By eliminating the need for kill fluids, you prevent formation damage. The well can return to its full production potential immediately after the intervention. ✅ OPEX Optimization: Significant cost savings are achieved by reducing the need for kill fluids, vacuum trucks, and specialized disposal services. ✅ Flexible Deployment: The tool can be run on the rod string with the pump or pre-set on the tubing for a simple latch-in operation.

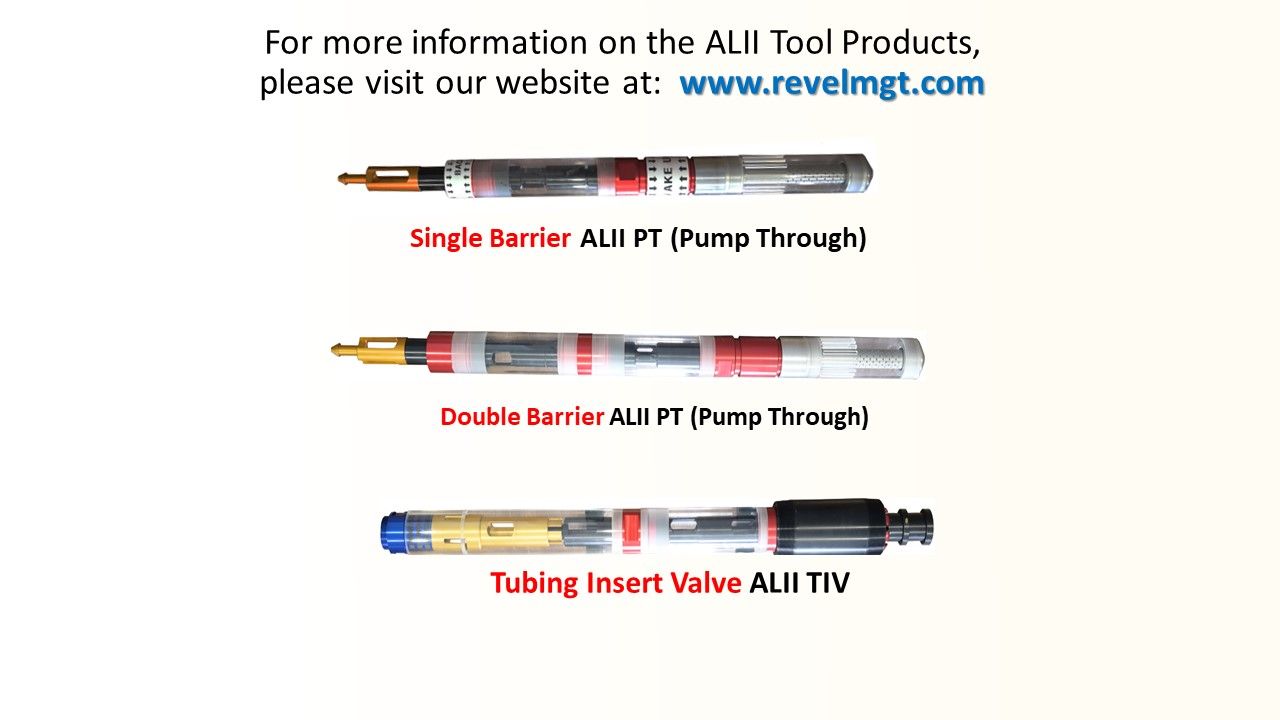

Enhanced Safety: Based on specific requirements, we have developed a dual-valve version for redundant isolation.

Corrosion Resistance: The tool is designed for harsh environments, and we are prepared to utilize advanced metallurgical solutions for even more aggressive conditions.

Beyond SRP: We are ready to develop an ESP-compatible version upon customer request. We welcome the opportunity to collaborate and solve your specific intake isolation challenges.

ALII is an investment in faster workovers and long-term reservoir health.

Let’s discuss how we can adapt this technology to your field requirements.