As the end of 2025 approaches, it is a natural time to reflect on lessons learned, assess performance, and move forward with confidence. One area where this reflection is especially valuable is in the continued deployment and evolution of our ALII Tool.

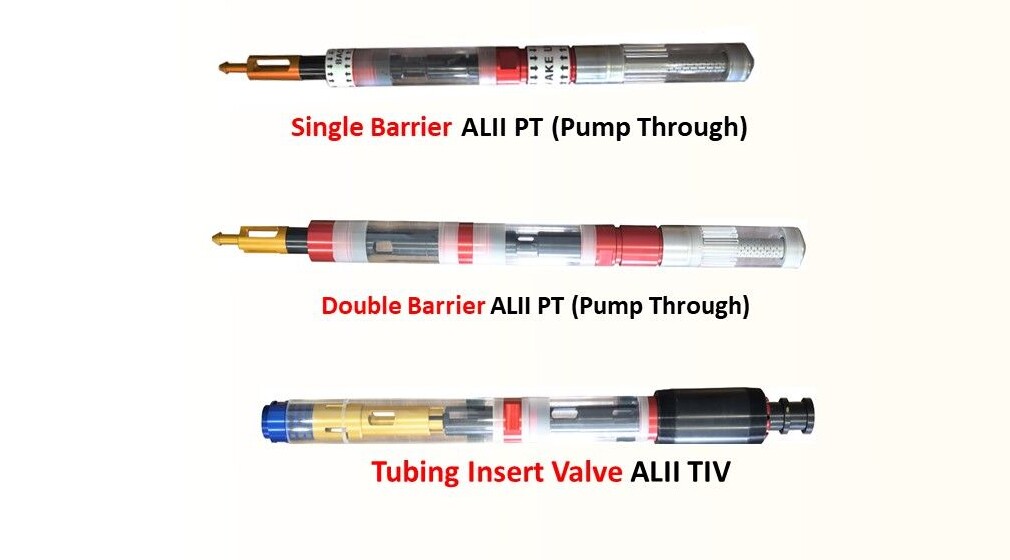

The ALII Tool is a tubing isolation valve designed to provide positive well control before breaking wellhead containment. It operates using the existing rod string and sucker rod pump, allowing operators to open and close the valve without introducing additional complexity into the well design. No external control lines, clamps, bands, or auxiliary components are required.

Improving Well Control While Reducing Risk

By isolating the tubing annulus, the ALII Tool significantly reduces the number of well kill operations required during pump changeouts and maintenance. This delivers several important benefits:

-

Lower operating costs by eliminating unnecessary well kill procedures

-

Reduced formation damage, which commonly occurs during traditional interventions

-

Lower methane emissions, the primary greenhouse gas associated with well interventions

Together, these benefits translate into safer operations, improved environmental performance, and a measurable contribution to emissions reduction.

Proven Performance in Demanding Environments

In previous years, we successfully deployed 75 ALII Tools on pumpjack-operated wells for a major Canadian operator. These tools have been operating in high-H₂S environments and elevated temperatures, providing valuable long-term field data.

One of the key challenges identified through this experience has been steel corrosion. Over the past year, we have implemented multiple mitigation measures to address this issue.,.

Recently, we received an ALII Tool that had been in continuous service for five years. The inspection results were highly encouraging:

-

Cylinders, plungers, and threads were in good, fully serviceable condition

-

No H₂S-induced cracking was observed

-

No deposits were present

-

All internal channels were clean

These findings validate both the original design and the effectiveness of the corrosion mitigation measures introduced over time.

Advancing to the Next Generation

In parallel with field operations, we are actively testing the next generation of corrosion-resistant coatings. Early results indicate even stronger performance in high-H₂S environments, reinforcing our confidence that future ALII Tool deployments will achieve extended service life and even greater reliability.

As we look toward the next phase of development, our focus remains clear: deliver practical, field-proven technology that improves well control, reduces environmental impact, and supports responsible operations across the industry.